The automotive sector faces several important challenges when it comes to traceability. Here are some of these challenges:

Quality and safety of products

One of the main challenges for the automotive industry is to ensure the quality and safety of vehicles. Traceability is essential to track the components and materials used in car manufacturing, ensuring that they meet quality and safety standards. This also allows for the retracing of production, assembly, and distribution processes to detect and quickly resolve quality issues or manufacturing defects.

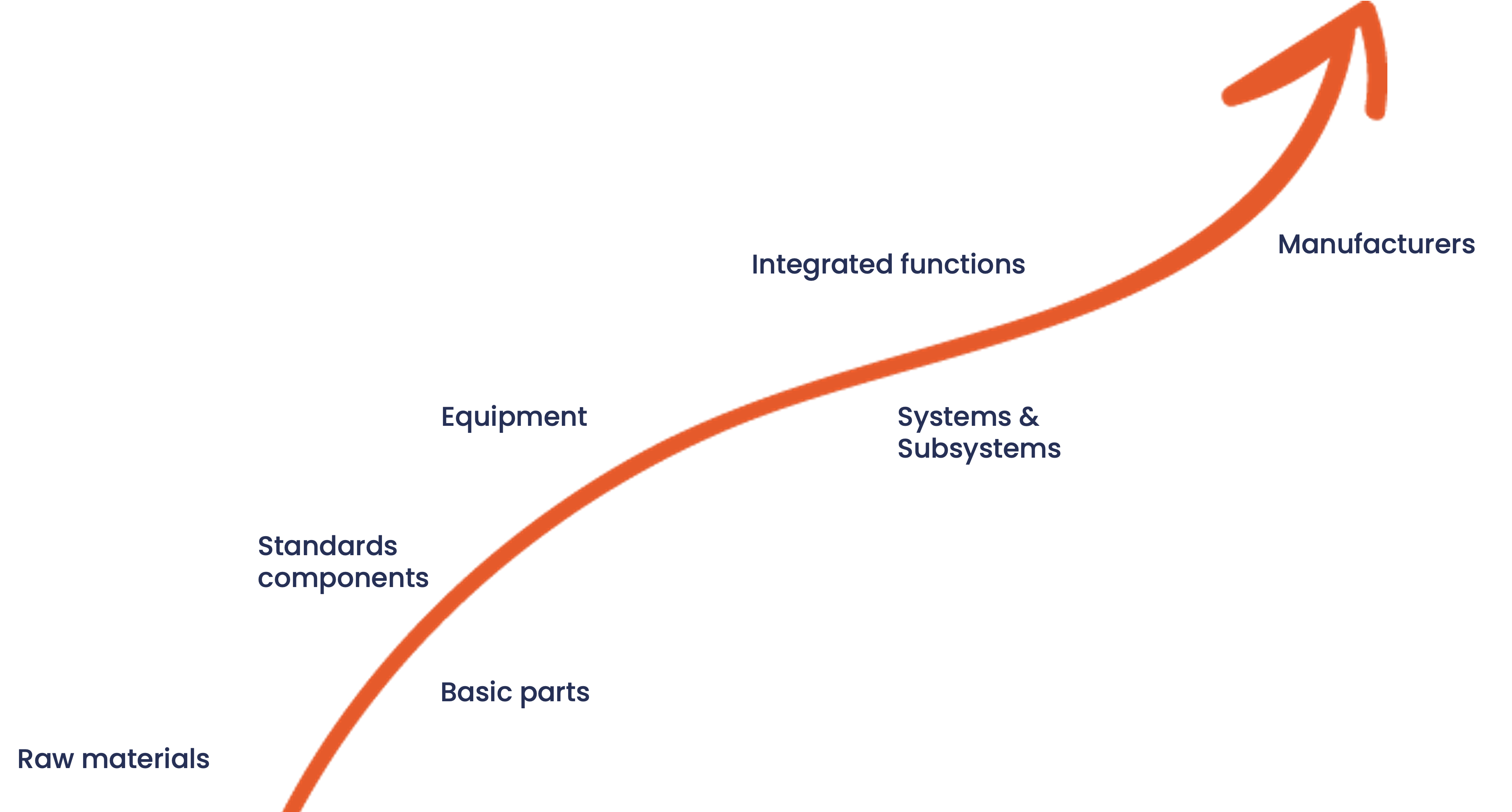

Supply chain management

The automotive industry has complex and global supply chains involving many suppliers and subcontractors. Traceability is necessary to track parts, components, and materials throughout the supply chain, ensuring the availability of parts, managing inventory effectively, and optimizing production planning.

Regulatory compliance

The automotive sector is subject to strict regulations regarding vehicle safety, emissions, energy efficiency, recycling, etc. Traceability is essential to comply with these regulations, providing evidence of compliance, recording information on components and manufacturing processes, and facilitating regulatory audits and inspections.

Recall management

In case of defects or safety issues identified in vehicles, traceability allows for the rapid identification of affected vehicles and the implementation of corrective actions, including product recalls. It facilitates communication with customers and regulatory authorities, ensuring a quick and effective response to safety issues.

Sustainability and environmental responsibility

The automotive industry is increasingly concerned with environmental sustainability and social responsibility. Traceability can help track the origin of materials used, environmentally friendly manufacturing practices, fair working conditions, etc. This allows automakers to demonstrate their commitment to sustainability and social responsibility, meeting consumer and stakeholder expectations.

Innovation and technological evolution

Traceability can also play a role in the innovation and technological evolution of the automotive industry. It allows for the tracking of new technologies, software updates, and improvements made to vehicles, facilitating maintenance, updates, and future improvements.

In summary, traceability is crucial in the automotive sector to ensure quality, safety, compliance, effective supply chain management, sustainability, and social responsibility. It also helps manage product recalls and support technological innovation in the industry.

Predell Trace: a perfectly adapted response to these challenges

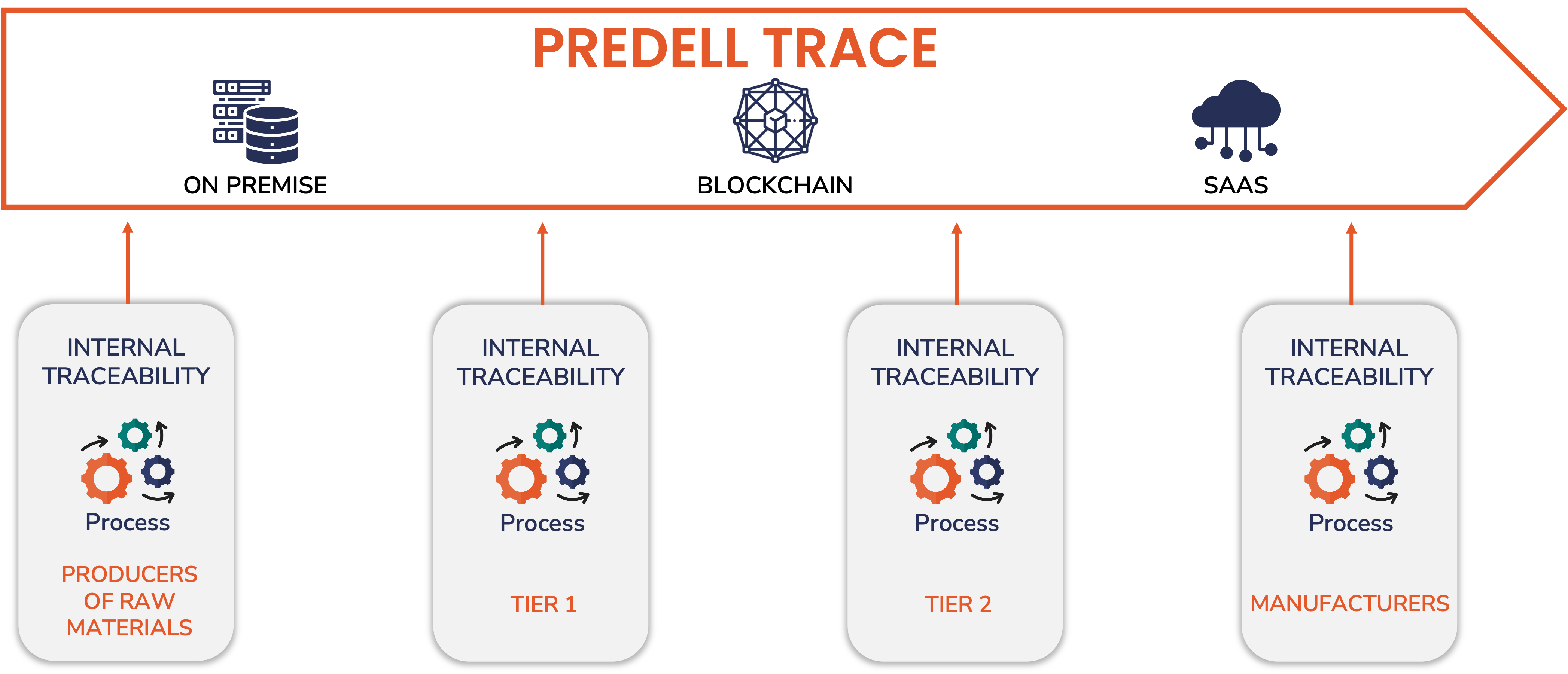

Predell Trace is an end-to-end traceability solution specifically designed to address any type of issue with great flexibility.

he architecture of Predell Trace is open to any type of traceability. It is based on a traceability engine that allows precise tracking of all events occurring during the circulation of individual objects or product batches in the different locations of the supply chain.

The data processed by Predell Trace is automatically imported from the information systems of the traceability stakeholders (suppliers, transformers, logisticians, etc.). Whether it is VSEs or large companies, all these entities can transmit their Traceability data thanks to Predell solutions. The authenticity over time of the data used by Predell Trace can be certified thanks to a Blockchain connected to the platform.

Predell Trace has been specifically designed to address all these issues with great flexibility. The platform is based on a traceability engine that allows precise tracking of all Events (assembly, machining, assembly, etc.) applied to all types of components, to a subassembly or to the final equipment itself throughout its manufacturing process. Predell Trace can also ensure the traceability of objects not belonging to the physical world such as documents, transactions, or identifiers having their representation in any type of universe.

The data corresponding to the traceability events are communicated to Predell Trace by the information systems of the stakeholders in the value chain (Tier 1 and 2 suppliers, manufacturers, logistics providers, etc.) and without any format constraint.

The platform then processes them automatically, ensuring:

Their storage in a database according to a configurable model (it is for example possible to add CSR data).

The guarantee of data authenticity thanks to a blockchain.

The association of documents with any type of operation or object (certificate, control range, certification document, etc.).

Visual restitution on a web portal of traceability data, notably thanks to a multi-criteria search engine. These restitutions are carried out while respecting the authorizations linked to the different user profiles.

In “manual” mode, it is always possible to enter the necessary information for traceability through a user portal. This allows for assistance in establishing traceability links (correspondence between outgoing and incoming objects).

Our solution is based on a redundant and robust micro-services architecture that optimizes processing and offers availability adapted to user needs. Predell Trace is available in SaaS mode or license in a virtualized environment (Kubernetes).