Defense industry manufacturers face several important challenges when it comes to traceability:

National Security Challenges

The defense industry plays a crucial role in a country’s national security. Traceability is essential to ensure the origin and authenticity of equipment, weapons, and technologies used in the defense sector. It helps prevent the use of counterfeit parts, guarantees product quality, and minimizes the risks of security compromise.

Protection of sensitive technologies

Defense industry manufacturers work on sensitive and classified technologies, such as communication systems, missiles, radars, etc. Traceability is necessary to track the lifecycle of these technologies, from their design to their deployment, to prevent leaks of sensitive information and protect national interests.

Regulatory compliance

The defense industry is subject to strict regulations regarding export controls, data security, and compliance with national and international standards. Traceability is necessary to ensure that defense products and technologies comply with these regulations and security requirements.

Supply chain management

The defense industry’s supply chains can be complex and extensive, involving many suppliers and subcontractors. Traceability is essential to track components, materials, and processes throughout the supply chain, ensuring compliance, security, and product reliability.

Operational capability maintenance

Traceability is crucial for maintaining the operational capability of armed forces. It allows for tracking maintenance, repairs, and equipment upkeep, ensuring their availability and optimal functioning, and planning military operations accordingly.

Counterfeit protection

The defense industry faces the risk of equipment and component counterfeiting. Traceability helps combat counterfeiting by providing visibility into product origins and enabling their authentication.

Traceability is therefore essential for defense industry manufacturers to ensure security, compliance, protection of sensitive technologies, and effective supply chain management in the context of defense and national security.

Predell Trace: a perfectly adapted response to these challenges

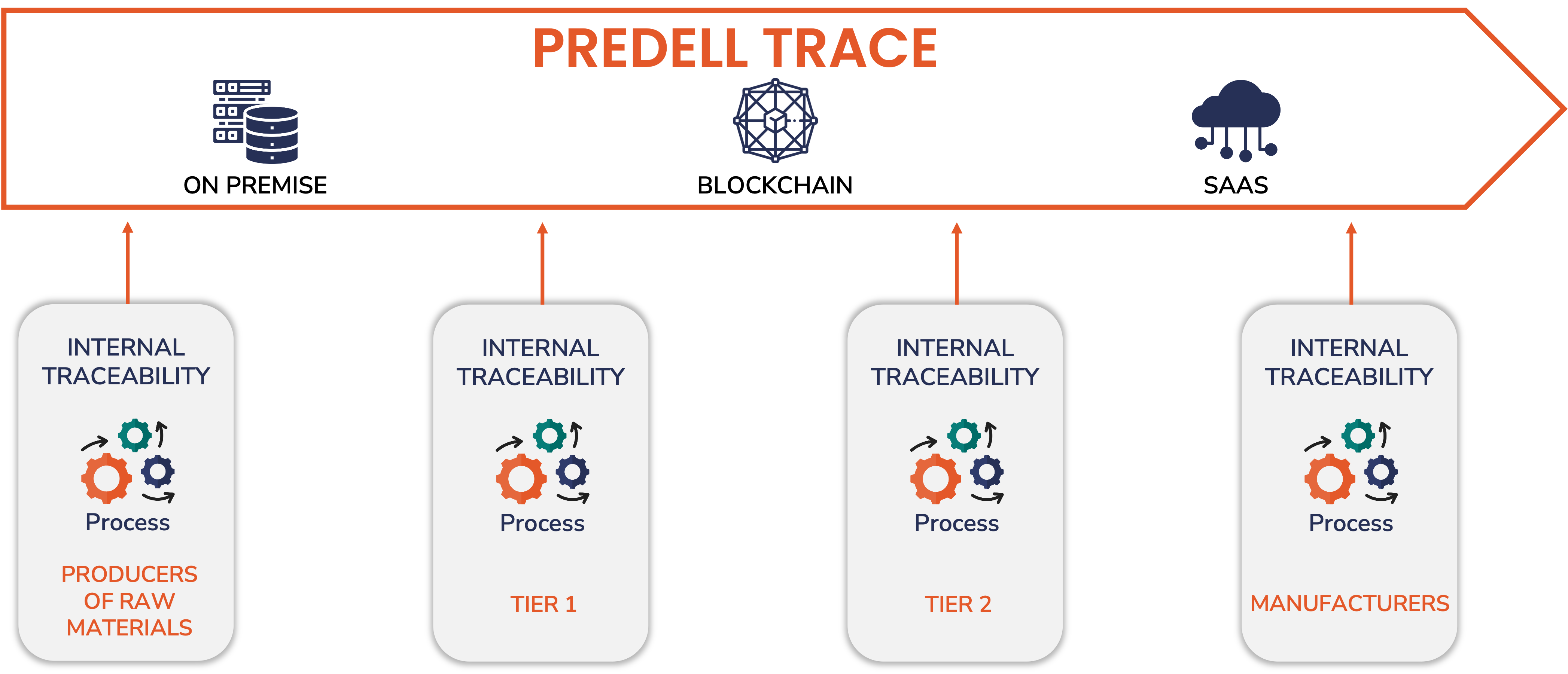

Predell Trace is an end-to-end traceability solution specifically designed to address any type of issue with great flexibility.

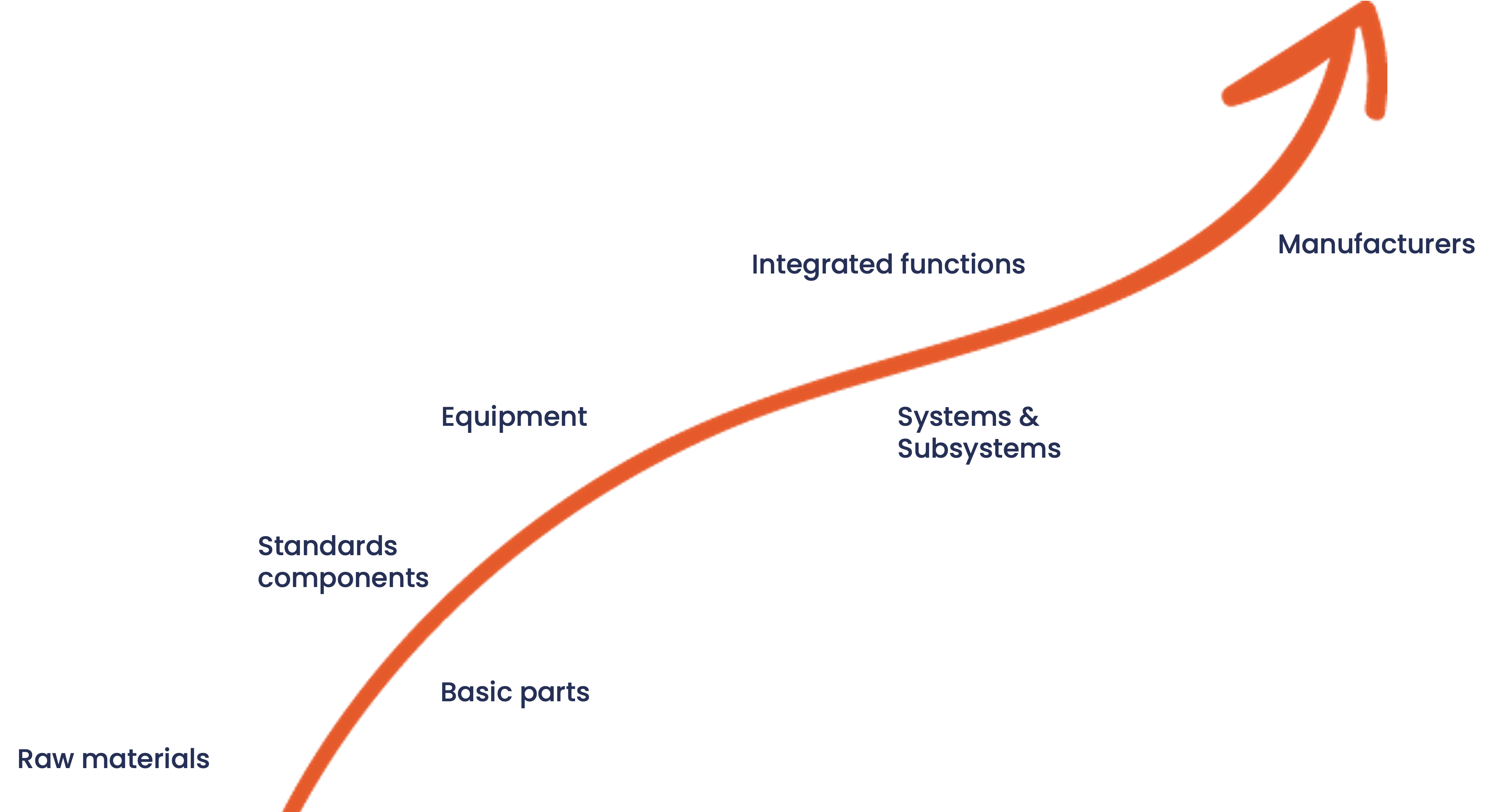

The architecture of Predell Trace is open to any type of traceability. It is based on a traceability engine that allows precise tracking of all events occurring during the circulation of individual objects or product batches in the different locations of the supply chain.

The data processed by Predell Trace is automatically imported from the information systems of the traceability stakeholders (suppliers, transformers, logisticians, etc.). Whether it is VSEs or large companies, all these entities can transmit their Traceability data thanks to Predell solutions. The authenticity over time of the data used by Predell Trace can be certified thanks to a Blockchain connected to the platform.

Predell Trace has been specifically designed to address all these issues with great flexibility. The platform is based on a traceability engine that allows precise tracking of all Events (assembly, machining, assembly, etc.) applied to all types of components, to a subassembly or to the final equipment itself throughout its manufacturing process. Predell Trace can also ensure the traceability of objects not belonging to the physical world such as documents, transactions, or identifiers having their representation in any type of universe.

The data corresponding to the traceability events are communicated to Predell Trace by the information systems of the stakeholders in the value chain (Tier 1 and 2 suppliers, manufacturers, logistics providers, etc.) and without any format constraint. The platform then processes them automatically, ensuring:

Their storage in a database according to a configurable model (it is for example possible to add CSR data).

The guarantee of data authenticity thanks to a blockchain.

The association of documents with any type of operation or object (certificate, control range, certification document, etc.).

Visual restitution on a web portal of traceability data, notably thanks to a multi-criteria search engine. These restitutions are carried out while respecting the authorizations linked to the different user profiles.

In “manual” mode, it is always possible to enter the necessary information for traceability through a user portal. This allows for assistance in establishing traceability links (correspondence between outgoing and incoming objects).

Our solution is based on a redundant and robust micro-services architecture that optimizes processing and offers availability adapted to user needs. Predell Trace is available in SaaS mode or license in a virtualized environment (Kubernetes).